We are Manufacturer, Supplier, Dealer, Distributor, Trader of Combo Tester, Surface Resistivity Meter, Wriststrap Tester, Common Ground Point Z111, Continuous Workstation Monitor Z107, Electrostatic Alarm - Z201, ESD Access Control System Z2056A, Human Body Voltage Checker Z2055 & Z2055A, Static Discharge Palmplate Z103P, Static Discharge Stand Z103D, Static Eliminator, Static Meter and our setup is situated in Pune, Maharashtra, India.Majorly we targeted customers from Satara, Nashik, Sinnar, Chakan, Savardari, Shirval (Shirwal) MIDC, Shivane, Dhayari, Sinhagad Road, Ramtekadi, Hadapsar, Aurangabad, Raigad.

COMBO TESTER Z124

OPTIONAL: Stand Z124S / Footplate Z124F / Wall station Z124W

Wrist straps and ESD footwears are the first lines of defence against electrostatic charge build up on the human body. They are designed to carry away this charge as soon as it is generated. At the same time, the wrist strap/footwear must remain electrically safe for the user. Thus, it is important to test every wrist strap/footwear regularly.

In order to protect sensitive electronic components, the maximum wrist strap resistance should not be more than 10 megohms and Footwear resistance should not be more than 35 Mega ohms. On the other hand, the resistance should not be less than 0.75 Mohm as protection to the wearer from dangerous levels of voltage and current flow.

This COMBO TESTER is a combination Wriststrap & DUAL footwear tester which checks these parameters under actual realtime operating conditions. The footwear section gives a warning if either of the Footwear is defective.

Combo Tester

Stand Z124S

Wall station Z124W

Footplate Z124F

| Pass Range | Wrist strap 0.75 to 10.0 meg ohm Footwear 0.75 to 35.0 meg ohm |

| Actuation | By gently pressing respective buttons |

| Accuracy | ± 10% |

| Power Requirement | 9 V DC battery. |

| Low Battery | Orange - Warning less than 7 volts. |

| Dimensions & Wt | (instrument) 125 x 75 x 29 mm 150 gms (stand) 400 x 400 x 950 mm ht. 5 Kgs |

| Calibration | Recommended every 12 months. |

| Traceability | To national standards |

| Warranty | 12 months |

COMBO TESTER Z134 + STAND Z134S (optional)

(with access control)

Wrist straps and ESD footwears are the first line of defence against electrostatic charge build up on the human body. They are designed to carry away this charge as soon as it is generated. At the same time, the wriststrap/footwear must remain electrically safe for the user. Thus, it is important to test every wrist strap/footwear regularly.

The maximum wrist strap resistance should not be more than 10 meg ohms and Footwear resistance should not be more than 35 Mega ohms. Also the resistance should not be less than 0.75 Mohm as protection to the wearer from dangerous voltages.

This COMBO TESTER is a combination Wriststrap & DUAL footwear tester which checks these parameters under actual realtime operating conditions. The footwear section gives a warning if either of the Footwear is defective. This is done by keeping 1 foot on the plate at a time.

Door Access System:

Before entering the EPA (ESD Protected Area) personnel need to test their Wrist Strap/ESD footwear. Access into the EPA is allowed by the release of the Electromagnetic lock only if the resistance of the Wrist Strap/ESD footwear is within the Pass limits.

SPECIFICATIONS :

| Pass Range | Wrist strap 0.75 to 10.0 meg ohm Footwear 0.75 to 35.0 meg ohm |

| Actuation | By gently pressing TEST button |

| Accuracy | ±10% |

| Power supplies | Included |

| EM Lock | Optional |

| Dimensions & Wt | (instrument) 125 x 75 x 29 mm 150 gms (optional stand) 400 x 400 x 950 mm ht. 5 Kgs |

| Calibration | Recommended every 12 months. |

| Traceability | To national standards |

| Warranty | 12 months. |

SURFACE RESISTIVITY METER Z203

This is an ultra wide-range, battery operated, portable instrument for measuring Surface Resistivity of virtually any flat surface. In the circuit industry, products such as packaging materials, component storage bags and trays, workbench surfaces, table and floor mats, conveyor belts, etc., have resistance values which need to conform to stringent specifications. Moreover, these values are expected to fall within specified limits. The Surface Resistivity meter can play a vital role in monitoring and checking the resistivity characteristic of the above items.

It also has a unique additional feature of surface-to-ground measurement capability wherein the resistivity differential between any surface and any chosen ground can be determined.

The surface resistivity is conveniently indicated by a row of LEDs covering a total of 10 decades from 10^3 to 10^13 ohms/square.

SPECIFICATIONS :

| Measurement Range | 10^3 to 10^13 ohms/sq |

| Measurement accuracy | half decade |

| Resolution | One decade. |

| Excitation voltage | 9 V |

| Indication | Visual by LEDs |

| Test actuation | Press to ON Switch. |

| Power supply | 9 Volt DC battery |

| Low battery | Warning at 7.5 V |

| Dimensions in mm | 125 x 75 x 29 |

| Weight | 150 GMS |

| Calibration | Recommended every 12 months |

| Traceability | To national standards |

| Warranty | 12 months |

| Accessories included | 1 m Grounding Cord & Carrying case |

SURFACE RESISTIVITY METER Z203-100

OPTIONAL EXTERNAL PROBES

This is a wide-range, battery operated, portable instrument for measuring Surface Resistivity of virtually any surface. In the circuit industry, products such as packaging materials, component storage bags and trays, work bench surfaces, table and floor mats, conveyor belts, etc., have resistance values which need to conform to stringent specifications. Moreover, these values are expected to fall within specified limits. The Surface Resistivity meter can play a vital role in monitoring and checking the resistivity characteristic of the above items.

Surface Resistivity, Resistance between 2 points, and Surface to Ground can all be conveniently measured in accordance with EOS/ESD Association Std S4.1. Measurements in the conductive range i.e. upto 10^5 are made at 10V and all higher values at 100V. Measurements can be taken with built-in parallel electrodes or special external probes. A separate cord is also provided for Surface to ground measurements whereby the resistivity differential between any surface and any chosen ground can be determined.

The surface resistivity is conveniently indicated through an LED scale that is colour coded to signify conductive, dissipative and insulative covering a total of 12 decades from 10^3 to 10^12 ohms/square with under range and over range indications.

SPECIFICATIONS :

| Measurement Range | autoranging 10^3 to 10^12 ohms/sq |

| Measurement accuracy | half decade |

| Resolution | One decade. |

| Excitation voltage | 10V for <10^5, 100V for >10^6 |

| Indication | By Multi-colour LEDs |

| Test actuation | Press-to-ON Switch. |

| Power supply | 9 Volt DC battery |

| Low battery | Warning at 7.5 V |

| Dimensions in mm | 125 x 75 x 29 |

| Weight | 160 GMS |

| Calibration | Recommended every 12 months |

| Traceability | To national standards |

| Warranty | 12 months |

| Accessories included | 1 m Grounding Cord & Carrying case |

| Optional | External measuring probes |

SURFACE RESISTIVITY METER ZE203

This is a wide-range, battery operated, portable instrument for measuring Surface Resistivity of virtually any flat surface. In the circuit industry, products such as packaging materials, component storage bags and trays, work bench surfaces, table and floor mats, conveyor belts, etc., have resistance values which need to conform to stringent specifications. Moreover, these values are expected to fall within specified limits. The Surface Resistivity meter can play a vital role in monitoring and checking the resistivity characteristic of the above items.

It also has unique additional feature of surface-to-ground measurement capability wherein the resistivity differential between any surface and any chosen ground can be determined.

The surface resistivity is conveniently indicated by a row of LEDs covering a total of 10 decades from 10^3 to 10^12 ohms/square.

SPECIFICATIONS :

| Measurement Range | 10^3 to 10^12 ohms/sq |

| Measurement accuracy | half decade |

| Resolution | One decade. |

| Excitation voltage | 9 V |

| Indication | Visual by LEDs |

| Test actuation | Press to ON Switch |

| Power supply | 9 Volt DC battery |

| Low battery | Warning at 7.5 V |

| Dimensions in mm | 125 x 75 x 29 |

| Weight | 150 GMS |

| Calibration | Recommended every 12 months |

| Traceability | To national standards |

| Warranty | 12 months |

| Accessories included | 1 m Grounding Cord & Carrying case |

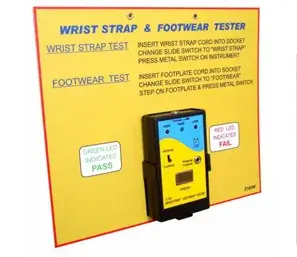

WRIST STRAP & FOOTWEAR TESTER Z103

(optional: Wall Station Z103W & Footplate Z103F)

Wrist straps and ESD footwears are the first lines of defence against electrostatic charge build up on the human body. They are designed to carry away this charge as soon as it is generated. At the same time, the wrist strap/footwear must remain electrically safe for the user. Thus, it is important to test every wrist strap/footwear regularly.

In order to protect sensitive electronic components, the maximum wrist strap resistance should not be more than 10 meg ohms and footwear resistance should not be more than 35 Mega ohms. On the other hand, the resistance should not be less than 0.75 Mohm as protection to the wearer from dangerous levels of voltage and current flow.

The wrist strap and the footwear tester checks these parameters under actual operating conditions with the strap on the wrist or footwear to the foot. It clearly indicates whether or not the wrist strap/footwear system is safe to use.

SPECIFICATIONS :

| Pass Range | Wrist strap 0.75 to 10.0 meg ohm. Footwear 0.75 to 35.0 meg ohm. |

| Range selection | by Slide Switch 10 meg ohms - Wrist Strap 35 meg ohms - ESD Footwear / Heel & Toe strap. |

| Indications | Pass - GREEN LED Fail - RED LEDS Audible Alarm for Fail mode. |

| Actuation | By gently pressing metal sensor plate |

| Accuracy | ± 10% |

| Power requirement | 9 V DC battery |

| Low Battery | Warning less than 7 volts |

| Dimensions | 125 x 75 x 29 mm |

| Weight | 200 grams |

| Calibration | Recommended every 12 months |

| Traceability | To national standards |

| Warranty | 12 months |

WRIST STRAP & FOOTWEAR TESTER Z103-100

(optional: Wall Station Z103W & Footplate Z103F)

Wrist straps and ESD footwears are the first lines of defence against electrostatic charge build up on the human body. They are designed to carry away this charge as soon as it is generated. At the same time, the wrist strap/footwear must remain electrically safe for the user. Thus, it is important to test every wrist strap/test footwear regularly.

In order to protect sensitive electronic components, the maximum wrist strap resistance should not be more than 10 meg ohms and footwear resistance should not be more than 100 Mega ohms. On the other hand, the resistance should not be less than 0.75 Mohm as protection to the wearer from dangerous levels of voltage and current flow.

The wrist strap and the footwear tester checks these parameters under actual operating conditions with the strap on the wrist or footwear to the foot. It clearly indicates whether or not the wrist strap/footwear system is safe to use.

SPECIFICATIONS :

| Pass Range | Wrist strap 0.75 to 10.0 meg ohm. Footwear 0.75 to 100.0 meg ohm. |

| Range selection | by Slide Switch 10 meg ohms - Wrist Strap 100 meg ohms - ESD Footwear / Heel & Toe strap. |

| Indications | Pass - GREEN LED Fail (low) - RED LED Fail (high) - RED LED Audible Alarm for Fail mode. |

| Actuation | By gently pressing metal sensor plate. |

| Accuracy | ± 10% |

| Power requirement | 9 V DC battery |

| Low Battery | Warning less than 7 volts. |

| Dimensions | 125 x 75 x 29 mm |

| Weight | 200 grams |

| Calibration | Recommended every 12 months |

| Traceability | To national standards |

| Warranty | 12 months |

WRIST STRAP TESTER Z102

Wrist Straps are the first lines of defence against electrostatic charges build up on the human body. They are designed to carry away this change as soon as it is generated. At the same time the strap must remain electrically safe for the user. Thus, it is important to test every strap regularly.

In order to protect sensitive electronic components the maximum strap resistance should not be more than 10 meg ohms. On the other hand, the path to ground should have atleast 750 kiloohm resistance, as protection to the wearer from dangerous voltages and levels of current flow.

The wrist strap tester checks these parameters under actual operating conditions with the strap on the wrist. It clearly indicates whether or not the resistance of the strap system including the wearer falls within acceptable limits.

SPECIFICATIONS :

| Pass Range | 0.75 Megohms to 10 Megohms |

| Range selection | Pass - Green LED Fail - RED LED Audible Alarm for Fail mode. |

| Actuation | By gently pressing metal sensor plate. |

| Accuracy | ± 10%. |

| Power supply | 9 V volts battery |

| Dimensions | 125 x 75 x 29 mm |

| Weight | 200 gms (with battery) |

| Calibration | Recommended every 12 months. |

| Traceability | To national standards |

| Warranty | 1 year |

WRIST STRAP & FOOTWEAR TESTER ZE103

(optional: Footplate Z103F & Wall Station Z103W)

Wrist straps and ESD footwears are the first lines of defence against electrostatic charge build up on the human body. They are designed to carry away this charge as soon as it is generated. At the same time, the wrist strap/footwear must remain electrically safe for the user. Thus, it is important to test every wrist strap/test footwear regularly.

In order to protect sensitive electronic components, the maximum wrist strap resistance should not be more than 10 meg ohms and footwear resistance should not be more than 35 Mega ohms. On the other hand, the resistance should not be less than 0.75 Mohm as protection to the wearer from dangerous levels of voltage and current flow.

The wrist strap and the footwear tester checks these parameters under actual operating conditions with the strap on the wrist or footwear to the foot. It clearly indicates whether or not the wrist strap/footwear is safe to use.

SPECIFICATIONS :

| Pass Range | Wrist strap 0.75 to 10.0 meg ohm. Footwear 0.75 to 35.0 meg ohm. |

| Range selection | by Slide Switch 10 meg ohms - Wrist Strap 35 meg ohms - ESD Footwear / Heel & Toe strap. |

| Indications | Dual colour LED: Pass - Green Fail - Red Audible Alarm for Fail mode. |

| Accuracy | ± 10%. |

| Low Battery | Warning less than 7 volts. |

| Dimensions | 135 x 70 x 25 |

| Weight | 150 grams |

| Calibration | Recommended every 12 months. |

| Traceability | To national standards |

| Warranty | 12 months |

WRIST STRAP TESTER ZE102

Wrist Straps are the first lines of defence against electrostatic charges build up on the human body. They are designed to carry away this charge as soon as it is generated. At the same time the strap must remain electrically safe for the user. Thus, it is important to test every strap regularly.

In order to protect sensitive electronic components the maximum strap resistance should not be more than 10 meg ohms. On the other hand, the path to ground should have atleast 750 kiloohm resistance, as protection to the wearer from dangerous voltages and levels of current flow.

The wrist strap tester checks these parameters under actual operating conditions with the strap on the wrist. It clearly indicates whether or not the resistance of the strap system including the wearer falls within acceptable limits.

SPECIFICATIONS :

| Pass Range | 0.75 Megohms to 10 Megohms. |

| Indications | Pass - Green LED Fail - RED LEDs (High & Low) Audible Alarm for Fail mode. |

| Actuation | By Press to ON switch |

| Accuracy | ± 10%. |

| Power supply | 9 V volts battery |

| Dimensions | 135 x 70 x 25 |

| Weight | 100 gms |

| Calibration | Recommended every 12 months. |

| Traceability | To national standards |

| Warranty | 1 year |

As per ANSI/ESD S20:20 all conductors including Personnel must be electrically connected and attached to a known ground.

A common question about Antistatic wrist straps is how and where to ground them. Antistatic workstation operators need a convenient method of grounding their wrist straps where the ground cord won’t get in the way of their work. This convenient device provides the means to ground Antistatic wrist straps at your workstation.

The strong bracket mounts (with just 2 screws) to the bottom front edge of your work table or bench. Two banana sockets located in the front of the bracket allow for easy connection of two wrist strap cords (for operators working side by side).

Features :

- • Designed to mount under the bench, saving work surface space

- • 2 banana jacks allow for grounding two Antistatic wrist straps at once

- • Lug for attachment to earth ground

- • Front edge bench mounting of the ground block via two screw slots

| Dimensions | 125 x 75 x 29 mm |

| Weight | 175 gms |

| Construction | Black ABS with 2 nos 4mm banana sockets |

| Fixing | with 2 screws |

The Model Z107 has independent circuitry designed to continuously monitor the connections to earth of the Wrist Strap and Work Surface.

WRIST STRAP

This section continuously monitors the wriststrap to detect loss of continuity between operator and monitor. Conditions such as broken coil cords and improper contact with the skin are detected instantly to alert the operator before serious and expensive ESD damage can occur. As there is no resistive return path from the wriststrap, it uses the 'Capacitive AC principle' to check if the operator is adequately grounded. The Wrist Strap section is automatically activated when it is plugged in. Continuous monitoring reduces the need for periodic checks and audits and also ensures greater security.

WORK SURFACE (MAT)

The work surface is monitored by a DC Resistive loop and a warning is given in case the Surface-to-Ground resistance exceeds the safe threshold value of 10 megohms

SPECIFICATIONS :

| Pass Threshold | under 10 Megohms for Wrist Strap. |

| under 10 Megohms for MAT | |

| Indications | Pass - Green LED |

| Fail - Flashing Red LED for Wrist Strap Steady Red LED for MAT Audible Alarm for Fail mode. |

|

| Power supply | 6VDC 100ma |

| Dimensions | 110 x 60 x 32 mm |

| Weight | 75 gms |

| Calibration | Recommended every 12 months |

| Warranty | One year |

The Electrostatic Alarm Z201 is a portable, battery-operated instrument, incorporating the latest technology, to indicate the presence of approaching static electricity. It is designed to provide a quick and convenient method of locating static charges and their approximate charge levels. It is primarily intended for use in static-safe handling areas, as an early warning system to alert the personnel nearby.

The hazard may be in the form of personnel who are generating static or personnel who may be holding a charged object without observing the standard safety procedures for handling static sensitive devices.

The instrument incorporates a unique self-resetting feature and therefore requires no manual adjustments or zeroing. It can be kept 'ON' for continuous monitoring of critical static-safe areas, thanks to its remarkably low current drain of only 1 ma.

THEORY OF OPERATION

A static charge on an object produces an electric field whose strength is an inverse function of the distance from the charge. A given magnitude of charge always produces a given field strength at a given distance. The unique sensor of the instrument actually responds to this electric field. However, more specifically, it senses only changes in the electric field, so to detect a charge there should be relative motion between the instrument and the charged body.

SPECIFICATIONS :

| Detection method | Charge coupling by field interception. | ||

| Detection sensitivity | 100 V or more | ||

| Range selection |

Autoranging and autoresetting | ||

| Indication | By audible/visual alarm |

||

| Power supply | 9 V battery | ||

| Dimensions in mm | Table model - 125 x 75 x 29 | ||

| Weight | 150 gms 50 gms |

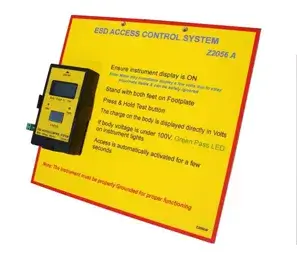

OPTIONAL: Wall station Z2056W

This instrument is designed to detect the level of Static Charges present on a human body and allow access into an ESD safe area provided the Body Static voltage is under 100V.

It is very simple to use and only requires the personnel to Press & Hold the Test Button on the instrument. If the Body voltage is under 100V, the Green PASS Led will light and the magnetic lock is deactivated for a few seconds thereby allowing access through a door or turnstile.

The personnel should normally be free of Static Voltage provided proper ESD protection measures have been taken. Therefore, it also serves to verify whether the measures are taken to make a particular area ESD safe are effective. By such measures we mean conductive flooring, ESD wrist straps & Footwear, ionizing equipment, etc.

| Dimensions in mm | 125 x 75 x 29 |

| Weight | 125 gms |

| Test Actuation | push button switch |

| Indicating range | 0 to ± 1999V |

| Warning | Audio alarm if voltage exceeds 100V |

| Display | 3.5 digit LCD display with polarity indication |

| Accuracy | ± 15% |

| Test Surface | Nickel plated button |

| Power Supply | 9VDC Power adaptor |

| Calibration | Recommended once every 12 months |

| Traceability | To national standards |

| Warranty | 1 Year |

| Accessories | Carrying Case & Grounding Cord |

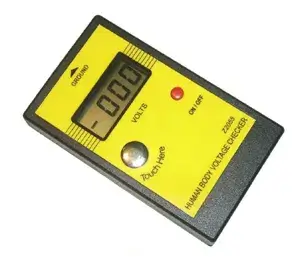

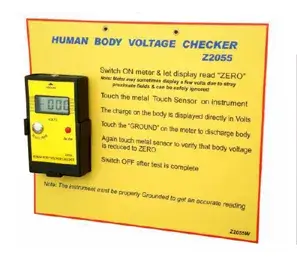

OPTIONAL : Wall station Z2055W

This instrument is designed to measure the Static Voltages carried on a human body. It is a good auditing tool to verify whether Personnel entering an ESD safe area are carrying any hazardous charges on themselves. It can also serve to verify whether all the ESD protection measures which have been taken to make a particular area ESD safe are effective. By such measures, we mean conductive flooring, antistatic table mats, wrist straps, static shielding bags, ionizing equipment, conductive containers and bins etc.

It is very simple to use and only requires the personnel under test to touch the Button on the instrument and directly read the charge level in volts on the meter.

The Z2055A version gives a hazard warning if Voltage measured exceeds 100V

SPECIFICATIONS :

| Dimensions in mm | 125 x 75 x 29 |

| Weight | 125 gm. |

| Test Actuation | On/Off push button switch |

| Indicating range | 0 to ± 2000V |

| Warning (in Z2055A) | Audio alarm if voltage exceeds 100V |

| Display | 3.5 digit LCD display with polarity indication |

| Accuracy | ± 15% |

| Test Surface | Nickel plated button |

| Power Supply | 9 V battery |

| Low battery | Warning at < 7.5 V on Display |

| Calibration | Recommended once every 12 months |

| Traceability | To national standards |

| Accessories | Carrying case & Grounding Cord |

| Accessories | Carrying case & Grounding Cord |

| Construction | ABS plastic cabinet |

| Warranty | 1 year |

The Grounding PALMPLATE is a convenient and quick solution to ensuring that there is no charge on the Human Body before entering any ESD safe area. It has a conductive Stainless Steel electrode plate mounted onto an acrylic backing.

The plate can be mounted on the wall at a convenient height and the personnel have to just touch the plate to drain any charge from the body.

The Plate is supplied with a Grounding cord which needs to be connected to any ESD earth point. A 2.2 megohm resistor is provided in the ground cord as a precaution against the risk of shock.

SPECIFICATIONS :

| Material | Stainless steel on Acrylic backing |

| Finish | Brushed effect |

| Dimensions | Touch Plate 150 x 150 mm |

| Weight | 500 gms |

| Decay Time | < 2 secs |

| Resistance to Ground: | 2.2Mohm |

| Dimensions in mm | 170 x 90 x 200 |

| Weight | 2.75 kgs |

This is designed to safely drain away any static charges present on a Human body before entering an ESD safe area. A 1 megohm resistor is provided in the ground cord as aprecaution against the risk of shock.

Ground the stand to a suitable ESD ground point by means of the cord.

Stand on the Base Plate while wearing the Conductive / Static Dissipative Footwear and also touch the top plate. Any static present on the body will get drained away.

Note: For outstation supplies to facilitate transport, the Stand will be sent in a dismantled condition. The 3 parts namely the top touch plate, base and the vertical rod have to be re-assembled and secured by means of the appropriate bolts and fasteners supplied.

SPECIFICATIONS :

| Material | Stainless steel & Block board |

| Finish | Brushed effect |

| Dimensions | Footplate 410 x 410 & 20mm Touch Plate 150 x 150mm |

| Weight | 4.75 Kg |

| Ht | 1000mm |

| Decay Time | < 2 secs |

| Resistance to Ground: | 1Mohm |

BAR TYPE - STATIC ELIMINATOR Z2075

The generation and accumulation of unwanted electrostatic charges, both surface and airborne, poses a serious problem in various industries and processes. For example, static charges can lead to sticking and crumpling of polyester films while being processed on the machines. Collection of dust and other particulate contaminants on surfaces due to static is another example. The discharge bars and the power supply are used primarily in cases where disruptive static charges on fast moving material webs impair production processes and need to be eliminated.

How it works

This static eliminator works on the principle of high voltage corona discharge, to produce the neutralising ions. This Static eliminator system is designed to neutralize the charges by the “Ion showering” process wherein the surface charges present are neutralised. It is designed for continuous use and the unique “Shockless bars” ensure total safety even if the electrodes are accidently touched.

Plastic film and paper industries, Glass related industries Textile Industries, Pharmaceutical industry, Clean rooms.

SPECIFICATIONS :

| HV Power supply | (LBH) 165 x 240 x 190 mm, 9.0 Kg |

| Input Supply | 3 PIN 230V AC 50Hz 50 Watts |

| Output voltage | 6 - 7 KV AC 5ma |

| No. of bars | Maximum 2 |

| Max load | Equivalent to 10m of cable including bars |

| Short circuit | Protection |

| Construction | Powder coated MS cabinet |

| Radiated EMI | Internally shielded |

| Ionizing Bar | Shockless SS electrodes with 2m cable |

| Neutralising distance | 50mm max from needle tip |

| Warranty | 12 months |

Note: Not to be used near flammable gases, vapours or materials.

OVERHEAD STATIC ELIMINATOR (IONIZER) Z209

The generation and accumulation of unwanted electrostatic charges, both surface and airborne, poses a serious problem in various industries, work areas & laboratories. For instance, static charges can cause havoc in the electronic assembly shopfloor.

This OVERHEAD unit can be conveniently hung over the work area for a large coverage to neutralise the charges on personnel or on any item entering an ESD sensitive area. This is achieved with a stream of ionized air. "Ion showering" is the only effective method of removing static charges from non-conductive objects and surfaces.

The unique high-efficiency pulse circuitry provides fast discharge with limited air flow. It works on the principle of high-voltage corona discharge to produce the neutralising ions.

Ion Balance is maintained irrespective of supply voltage and even if the discharge electrodes are dirty. Balanced output is essential when used in critical ESD sensitive areas.

ESD sensitive work areas and assembly units.

Plastic and paper industries

IT & Computer industry

Clean rooms.

SPECIFICATIONS :

| Air Flow | 425 cm/hr |

| Noise level | 55 dbA at 1m |

| Supply | 230V AC 50Hz 70 Watts |

| Ionization Potential | 6-8 KV |

| Ion balance | -/+ 50 V |

| Construction | Powder-coated Sheet metal enclosure |

| Dimensions in mm | L1000 x B170 x H130. |

| Weight | 7 kgs. |

| Warranty | 1 year. |

STATIC ELIMINATOR (IONIZER) Z207

The generation and accumulation of unwanted electrostatic charges, both surface and airborne, poses a serious problem in various industries and laboratories. For instance, static charges can create havoc with sensitive equipment and electronic components. This Bench Top instrument is designed to neutralise your ESD work-station or ESD protected area with a stream of ionized air. It does what Wrist straps and Conductive mats cannot do - i.e. remove static charges from non-conductive objects and surfaces.

It is able to rapidly neutralise potentially dangerous charges in a localised area. An axial fan gives the desired air flow to neutralise static on specific objects rapidly, as well as control static in the general area in front of the ionizer.

This is a powerful, trouble free and compact solution to static control problems anywhere. The unique high efficiency ionization pulse circuitry provides fast discharge with minimum air flow. A high air flow would lead to operator discomfort and may also disturb small components.

This static eliminator works on the principle of high voltage corona discharge to produce the neutralising ions. It is designed for continuous use and a current limitor circuit ensures operator safety even if the ion emitters are accidentally touched. The Z207 has special circuitry to ensure a balanced ion output. This ensures that no net charge is induced by the ion shower. Balance is maintained irrespective of supply voltage and even if the discharge electrodes are dirty. Balanced output is essential when used in ESD protected areas.

APPLICATION AREAS :

- Antistatic workstations and assembly units.

- Plastic film and paper industries

- Plastic manufacturing and moulding units.

- Pharmaceutical industry.

- Clean Rooms.

SPECIFICATIONS :

| Air Flow | 1.8 cu m/min |

| Noise level | 45 dbA (at 1m) |

| Supply | 230V AC 50Hz 20 Watts |

| Ionization voltage | 6-8 KV |

| Ion balance | under -/+ 50 V |

| Construction | Powder coated MS cabinet |

| Dimensions in mm | 170 x 90 x 200 |

| Weight | 2.75 kgs |

| Warranty | 1 year |

STATIC CHARGE METER (DIGITAL) Z205

The Static Charge Meter Z205 is a non-contact, light weight digital instrument designed to measure static voltages on objects & surfaces. It features a large LCD display to indicate the magnitude and polarity of the electrostatic charge directly in Kilovolts.

The special circuitry enables repeated and drift-free measurements without continual re-zeroing. The instrument has good directional sensitivity and is ideal for measuring electric charges encountered in critical electronic assembly and storage areas as well as Antistatic WorkStations. It can also be used for Plastics, Paper, Textiles, Food, Explosives and Pharmaceutical Industries.

The unit gives direct readings of electrostatic potentials on any surface, when held at a distance of 5 cms. However, higher electrostatic potentials can be measured by proportionately increasing the distance from the meter to the charged object.

The use of very low current circuitry results in a long battery life of over 6 months under normal use.

SPECIFICATIONS :

| Indicating range | ± 10 KV at 5 cms from object.(20KV on request) |

| Display | 3 1/2 digit LCD with polarity indication |

| Resolution | LSB 10V |

| Accuracy | ± 10% of Reading |

| Test Actuation | Push On push Off switch |

| Power Supply | 9 V battery |

| Low battery | Warning at 7.0 V on display |

| Dimensions in mm | 125 x 75 x 29 |

| Weight | 200 gms |

| Calibration | Recommended once every 12 months. |

| Traceability | To national standards |

| Warranty | 1 year |

| Accessories | Carrying case |